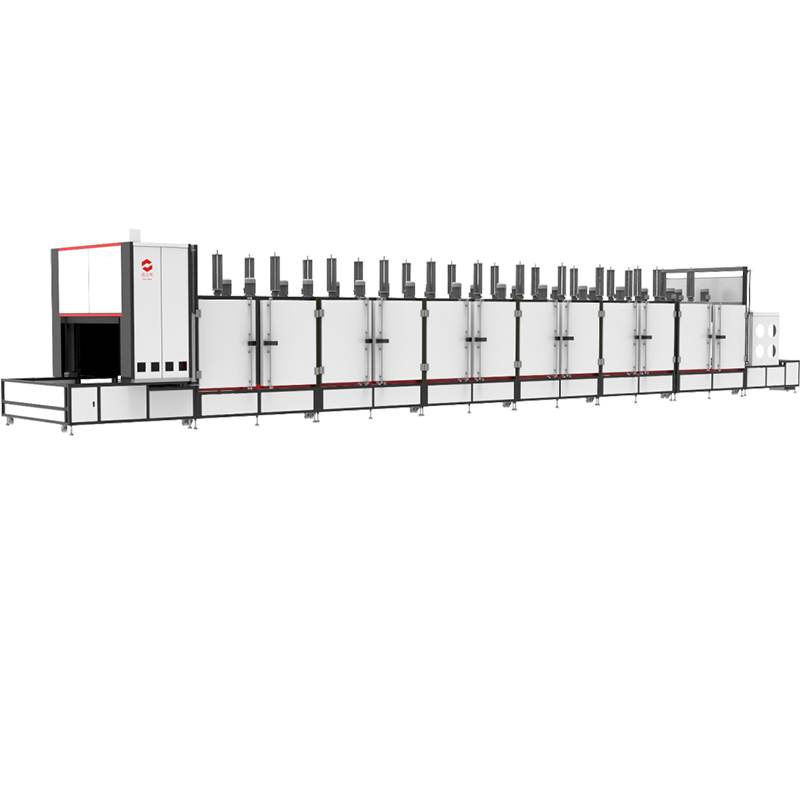

The Wicket Conveyor Tunnel Oven is a state-of-the-art solution designed to meet the increasing demand for efficient, high-quality PCB manufacturing. With its advanced features and cutting-edge technology, the oven is set to revolutionize the way PCBs are produced, offering a range of benefits to manufacturers.

One of the key features of the Wicket Conveyor Tunnel Oven is its energy-saving capabilities. The oven is equipped with advanced heating elements and energy-efficient technology, ensuring reduced power consumption without compromising on the quality of the PCBs. This is in line with Xinjinhui & Pengli's commitment to sustainability and environmental responsibility, as the company continues to prioritize the development of eco-friendly solutions for the industry.

In addition to its energy-saving capabilities, the Wicket Conveyor Tunnel Oven also offers superior performance and productivity. The oven is designed to provide consistent and uniform heating, ensuring that PCBs are baked to perfection with minimal variation. This level of precision and control is essential for achieving high-quality results in PCB manufacturing, making the oven an invaluable asset for manufacturers.

Furthermore, the Wicket Conveyor Tunnel Oven is equipped with a user-friendly interface and intuitive controls, making it easy to operate and monitor. This ensures that manufacturers can maximize efficiency and productivity, as well as maintain high levels of quality throughout the production process. The oven's advanced automation features also contribute to greater reliability and consistency, further enhancing its appeal to PCB manufacturers.

With the introduction of the Wicket Conveyor Tunnel Oven, Xinjinhui & Pengli aims to set new standards for PCB manufacturing and solidify its position as a leading provider of innovative equipment in the industry. The company's dedication to research and development has allowed it to continuously push the boundaries of technology, delivering solutions that address the evolving needs of the market.

"We are proud to introduce the Wicket Conveyor Tunnel Oven to the market, as it represents a significant milestone in our ongoing efforts to drive innovation in PCB manufacturing," said a spokesperson for Xinjinhui & Pengli. "By combining energy-saving capabilities with advanced performance and user-friendly design, we believe that the oven will have a transformative impact on the industry."

The introduction of the Wicket Conveyor Tunnel Oven comes at a time of rapid growth and expansion for Xinjinhui & Pengli, as it continues to gain recognition for its contributions to the PCB industry. The company's comprehensive range of intelligent screen printing machines and energy-saving tunnel ovens has earned it a reputation for delivering reliable and high-quality solutions that cater to the unique requirements of manufacturers.

As Xinjinhui & Pengli looks towards the future, it remains committed to driving progress and innovation in the PCB industry. By leveraging its expertise and experience, the company aims to develop even more advanced solutions that empower manufacturers to achieve new levels of efficiency, productivity, and quality in their operations.

The Wicket Conveyor Tunnel Oven is set to make a significant impact on the PCB manufacturing landscape, offering a combination of energy-saving technology, superior performance, and user-friendly design. As Xinjinhui & Pengli continues to lead the way in the development of innovative equipment, the company's vision for a more intelligent and sustainable PCB industry is becoming a reality.