Powder coating is a popular finishing process that creates a durable and attractive coating on various materials. However, to achieve high-quality and uniform results, the powder coating process requires the use of a specialized powder coating oven. Among the most popular types of powder coating oven is the custom air circulating oven. This blog will explore the key features, benefits, and uses of this type of oven.

What is a Custom Air Circulating Oven?

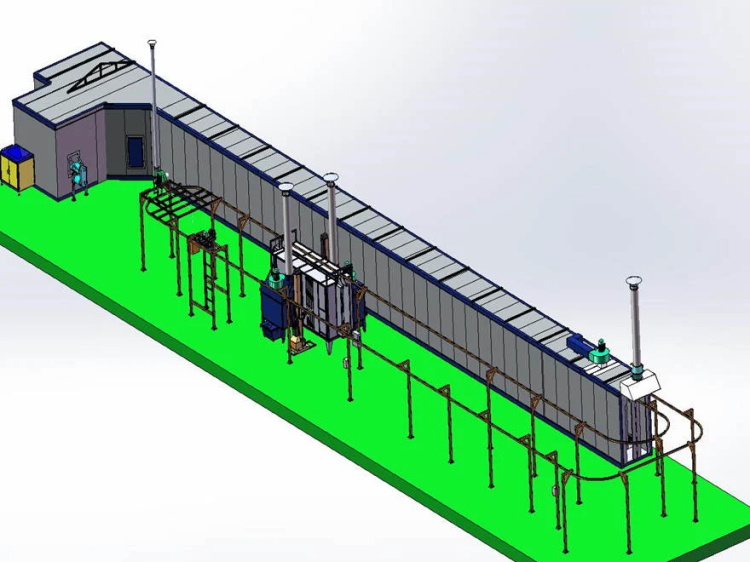

A custom air circulating oven is a type of powder coating oven that utilizes a fan to circulate hot air throughout the oven. This ensures even heating and curing of the powder coating, resulting in a durable and attractive finish. Custom air circulating ovens are designed to meet the specific needs of the user, including size, heat capacity, and other features.

Features of a Custom Air Circulating Oven:

1. Even Heating: The fan in a custom air circulating oven ensures that hot air is evenly distributed throughout the oven, resulting in uniform heating and curing of the powder coating.

2. Customizable: Custom air circulating ovens can be designed to meet the specific needs of the user, including size, heat capacity, and other features.

3. Compact Design: Custom air circulating ovens are designed to take up minimal floor space while still providing ample room for large products to be cured.

4. Safety Features: Custom air circulating ovens are equipped with safety features such as temperature controls, ventilation systems, and alarms to ensure safe and efficient operation.

Benefits of a Custom Air Circulating Oven:

1. Improved Efficiency: Custom air circulating ovens are designed to reduce energy consumption and improve production efficiency by ensuring even heating and curing of the powder coating.

2. Precision Curing: The even distribution of hot air throughout the oven ensures precise curing of the powder coating, resulting in a durable and attractive finish.

3. Cost-Effective: Custom air circulating ovens are designed to minimize energy consumption, resulting in cost savings for the user.

Uses of a Custom Air Circulating Oven:

1. Metal Fabrication: Custom air circulating ovens are commonly used in metal fabrication for the curing of powder-coated finishes on products such as metal parts, frames, and machinery.

2. Automotive Industry: Custom air circulating ovens are used in the automotive industry for the curing of powder-coated finishes on various parts such as wheels, bumpers, and body panels.

3. Home Improvement: Custom air circulating ovens are also used in the home improvement industry for the coating of various items such as iron railings, outdoor furniture, and garden fixtures.

Conclusion:

Custom air circulating ovens are a popular option for powder coating due to their even heating, customizable features, and cost-effectiveness. They are widely used in various industries, including metal fabrication, automotive, and home improvement. The use of a custom air circulating oven ensures precise curing of the powder coating, resulting in a durable and attractive finish.