In this blog, we will discuss the process and the benefits of applying UV curable solder mask. Additionally, we will talk about some of the top solder mask printer suppliers and what to consider when choosing the right one for your needs.

Understanding UV Curable Solder Mask

UV curable solder mask systems are the most commonly used type of solder mask in the electronics industry. These systems are designed to cure quickly under UV light, producing a durable and resistant coating. UV curable solder masks are available in different colors to provide high visibility and create a contrast. Some commonly used colors are green, blue, and red.

Applying UV Curable Solder Mask

There are several methods to apply solder masks, including screen printing, spray coiling, and roller coating. Among these, screen printing is the most popular method. Below are steps to apply UV curable solder mask via screen printing:

Step 1: Clean the Surface

Before applying the solder mask, the PCB must be cleaned thoroughly to remove any contaminants or debris. This process is essential as it ensures the surface is free from any impurities that might affect the adhesion of the solder mask.

Step 2: Prepare the Solder Mask

Mix the solder mask using the manufacturer's instructions. You can also add a color dye at this stage if desired.

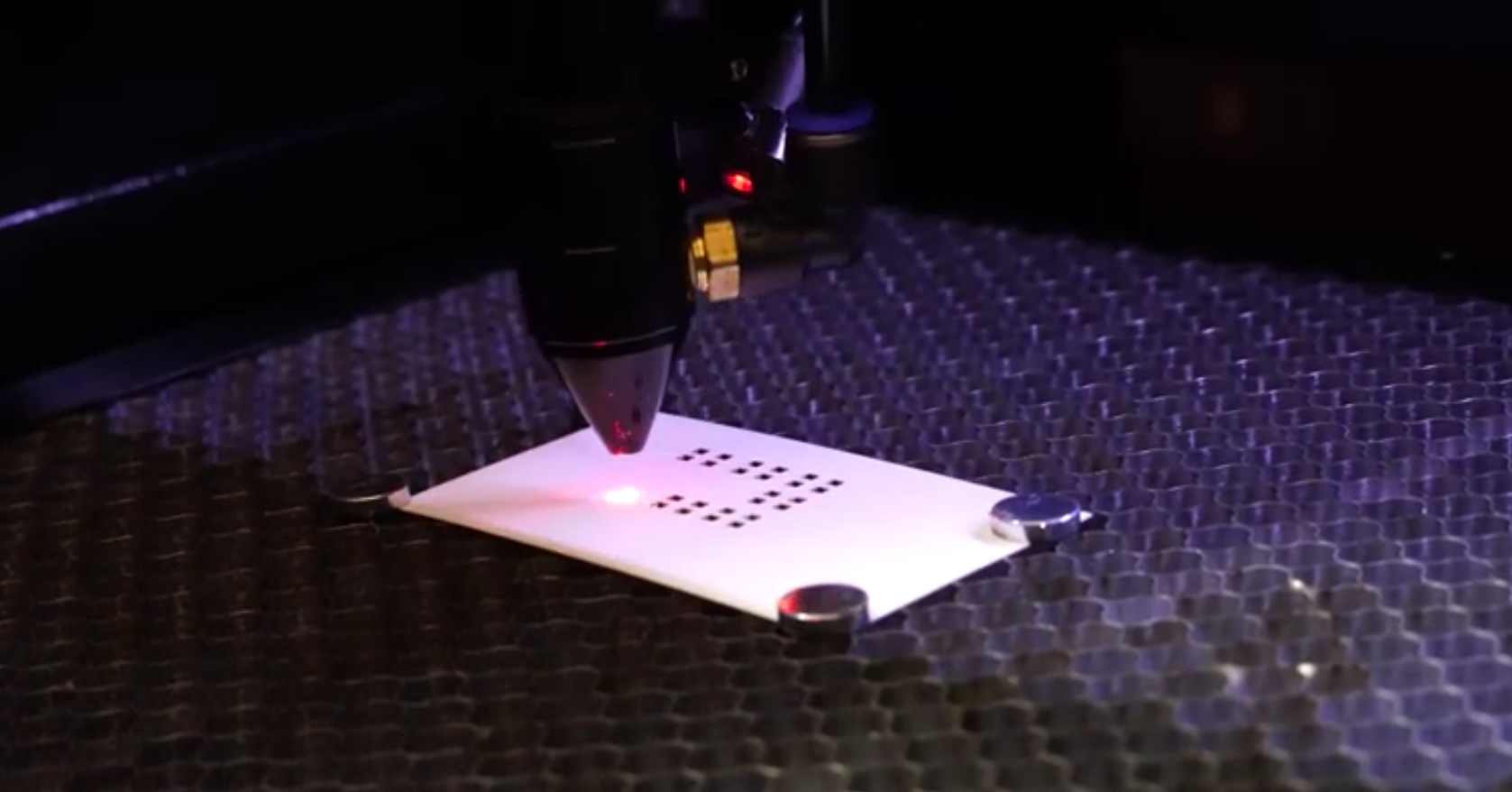

Step 3: Apply the Solder Mask

Once the PCB is clean and the mask is ready, apply the solder mask using a screen printer. The screen will only allow the solder mask to adhere to certain areas that must be masked. The remaining areas will be left uncoated for the subsequent soldering process.

Step 4: Dry and Cure the Mask

After applying the solder mask, it is essential to dry and cure it. This process is usually done in a UV curable oven or batch oven.

Benefits of UV Curable Solder Mask

UV curable solder mask offers several benefits, including:

Protection: Solder mask protects the PCB surface from dust, moisture, and adverse environmental effects.

Durability: UV curable solder mask is resistant to wear and tear, making it an ideal choice for applications that require constant exposure.

Solderability: Solder mask makes soldering easier and more efficient by creating a clean and consistent surface.

Solder Mask Printer Suppliers

Now that we understand the benefits of solder mask and how to apply it let's look at some of the suppliers of solder mask printers. Below are the top solder mask printer suppliers:

1. JEIL MTECH: JEIL MTECH is a Korean company that provides high-quality solder paste printers, dispensers, and conveyors.

2. EX-PROOF: EX-PROOF is a Taiwanese company that manufactures automated solder paste printers, including solutions for odd-shaped PCBs.

3. ITW EAE: ITW EAE provides a range of equipment, including solder paste printers, dispensers, and jetting systems.

4. MicroCraft: MicroCraft is a Japanese company that provides innovative and reliable solder paste printers.

Things to Consider When Choosing a Solder Mask Printer Supplier

Choosing the right supplier of solder mask printers requires careful considerations. Here are some factors to consider before making your decision:

Quality: Ensure that the supplier provides quality products and adheres to industry standards.

Reliability: Choose a supplier who provides prompt service and support if you encounter any issues with the equipment.

Cost: Solder mask printers can be expensive; consider choosing the one that is within your budget range.

Availability: Verify if the supplier has parts and consumables readily available to ensure that you do not experience production downtime.

Final Thoughts

Applying solder mask is a crucial step in PCB assembly, and using UV curable solder mask provides many benefits such as protection, durability, and improving solderability. Choosing a reliable and effective solder mask printer is essential to make the process more efficient and consistent. By considering factors such as quality, reliability, cost, and availability, you can choose the right supplier of solder mask printers for your needs.